Written with contributions by Kiernan Brandt, former SDSU Extension Cow/Calf Field Specialist.

Key Points

- Covering silage piles to exclude oxygen is critically important to control nutrient loss in silage.

- In research silos, covering with white-and-black plastic with or without oxygen barrier film was effective in minimizing storage losses.

- Condensed distillers solubles (abbreviated as CDS syrup), a by-product of ethanol production, was no better than using no cover at all in preventing organic matter losses.

- Silage inoculants improved fermentation when used in covered silos but were ineffective in uncovered silos or when syrup was used.

Silage plays a key role in supporting beef production in South Dakota. Whether the crop is corn, sorghum, or small grain, ensiling provides a method to preserve the crop in a palatable form that provides a great deal of flexibility to livestock producers.

However, to optimize nutrient capture, the entire harvest and storage process must be well-managed. Everything, including hitting harvest moisture targets, managing cut length, and achieving the correct bunker or pile density, is important in achieving a rapid pH drop and preserving crop nutrients. But perhaps the most-important step is the use of a cover to limit oxygen infiltration into the silage mass.

Unfortunately, covering a silage pile takes labor, one thing that is nearly always in short supply. First, the tarp needs to be put in place, followed by tires or some other method to secure the tarp in place. So, it is not surprising that farmers have sought out methods that reduce the amount of labor required or decide that the losses are acceptable and do not cover the pile at all.

Investigating Covering Strategies

SDSU Extension Specialists (led by Sara Bauder and Kiernan Brandt, along with Warren Rusche) set out in 2022 to test how much loss could be occurring following these strategies. They conducted a silage storage experiment using laboratory silos (3-foot long PVC pipe), using four different covering strategies: 1) no cover, 2) covered with CDS syrup, 3) covered with white-black plastic, and 4) covered with white-black plastic plus an oxygen barrier film. Each of these treatments were tested using corn silage with or without an inoculant applied.

Corn silage harvest occurred in August 2022. The corn was chopped to a one-half inch length of cut with a 66% harvest moisture content. The silage was packed into 3-foot by 8-inch PVC tubes to a packing density of 15 pounds of dry matter (abbreviated as DM) per cubic foot. The silage was allowed to ensile for 104 days before being opened, sampled, and analyzed.

Results

Inoculation did improve fermentation in the silos that were covered with one of the two forms of plastic. However, inoculated silage stored in uncovered silos, or when covered with CDS syrup, was no better than uninoculated.

The combination of white-black plastic plus an oxygen barrier did result in greater lactic acid content, indicating improved fermentation compared to white-black plastic alone. However, organic matter recovery was similar between the two forms of plastic covering.

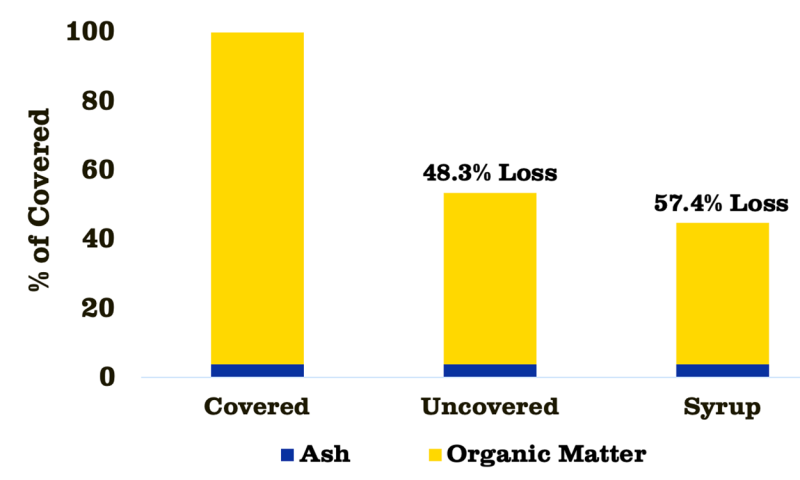

Organic matter losses were considerably greater, however, for uncovered silos and those covered with CDS syrup. In fact, using syrup was numerically worse than doing nothing at all. Organic matter losses relative to the plastic covered silos are shown in Figure 1.

In this chart, ash content is shown as a constant amount. In the uncovered and syrup, ash content as a percentage increased, indicating that there was a loss in organic matter.

Bottom Line

Farmers spend too much time, money, and resources to produce feed for their livestock only to lose it to spoilage. To best preserve nutrient value, there are no shortcuts. Every step needs to be taken to the best of our ability, and that includes using research-proven silage harvest management, like using effective covering methods.