Written collaboratively by Christina Bakker, Amanda Blair and the South Dakota Animal Industry Board.

This article is intended to provide guidance on the proper techniques for packaging meat and storing meat at home. If done correctly it will aid in ensuring meat product safety. If not done correctly there are significant foodborne illness risks.

Getting Started

Once meat has been fabricated and portioned into the desired cuts, it is time to package. Before packaging your cuts gather the appropriate materials and ensure all work surfaces are clean. For cuts such as chops or roasts, two main types of packaging are recommended: paper wrapping or vacuum sealing. Regardless of the type of packaging you choose, there are several principles of packaging that apply to all meat that will be frozen.

- Airtight. When food products are frozen in the presence of air, the products can become dehydrated resulting in what is commonly known as freezer burn. While freezer burn does not affect the safety of food products, it can cause off flavors and textures.

- Skintight. While airtight packaging does not allow outside air into the package, skintight packaging ensures that the amount of air within the package is minimal, which also helps to prevent freezer burn.

- Clearly labeled. All packages should be clearly labeled with at least the name of the cut and the date it was packaged. It may also be helpful to include how many pieces are in the package (i.e. 1 lb. of ground pork sausage or 4 pork chops). Most packaging methods for meat involve disposable materials that can be written on. You can use adhesive labels if you choose, just be sure the adhesive is freezer grade. Labels should be written legibly with a permanent marker.

Packaging

Paper Wrapping

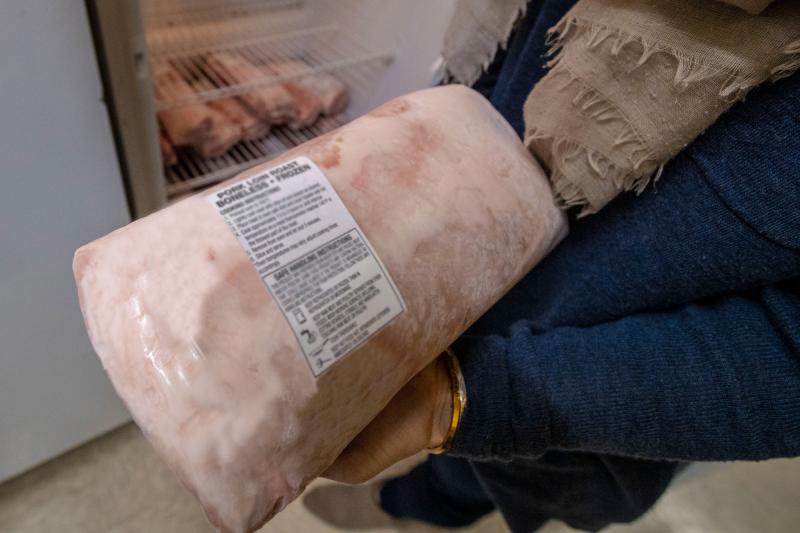

Wrapping cuts in freezer paper is usually the most cost-effective packaging option and can provide an airtight seal when done properly. Freezer paper can be obtained easily at most stores with a home food preservation section. Freezer paper is a two-ply paper that consists of paper outer layer and a thin plastic inner layer to ensure any liquid that may purge from the meat is contained. Most higher quality tapes will work to secure paper wrapping. If you are unsure if your tape will hold the wrapping under freezer conditions, special freezer tape is available. If you want an additional layer of protection, you can wrap the pieces of meat in plastic wrap before paper wrapping. You can also use plastic wrap as a barrier between chops to improve ease of separation after thawing. Paper wrapping can be difficult on irregular shapes such as bone in pork chops and is better suited for more regularly shaped cuts such as boneless roasts. However, with practice, it is possible to adequately wrap most meat products.

Vacuum Sealing

Vacuum packaging is a highly effective packaging method. The downside of vacuum sealing is the increased cost compared to paper wrapping.

The purchase of a vacuum sealer can be a larger investment than freezer paper and the bags can also be more costly. However, vacuum sealing is an excellent method to create and airtight, skintight barrier around the meat product.

When placing product into vacuum seal bags, it may be helpful to roll the top 2 inches of the bag down to keep it clean, allowing for a better surface for sealing.

Once sealed, inspect the package. If the bag did not seal, place the meat into a new bag and try again.

Helpful Tips

For both methods of packaging, use the smallest bag or piece of paper necessary to properly package the product for additional cost savings. Also, bone in products can puncture through packaging. For paper wrapping, you can use two pieces of paper and wrap normally. The extra layer of paper can help with tears and punctures.

For vacuum packaging, you can cut another vacuum bag into pieces small enough to cover the sharp edges giving another layer of protection. Also, bone guard material is commercially available and can be used in both methods.

This video from University of Alaska Fairbanks Extension shows the proper techniques for vacuum sealing and paper wrapping meat.

What not to do

- Do not use plastic grocery bags or garbage bags for storage. These plastics are not food grade and could transfer chemicals to the meat.

- Do not use zip-top bags for long term freezer storage. If you do decide to use zip-top bags, make sure they are freezer bags, not storage bags. These are not ideal for long term storage (i.e. more than a couple weeks) because they are difficult to make skintight and freezer burn is more likely with this method than other packaging methods.

- Do not package large quantities of meat together. The larger the packages are, the longer it will take for the packages to freeze. Package the meat in quantities that make sense for your needs. For instance, if you have 4 people in your family who will usually eat one chop each, package 2 or 4 chops together. Ground product is commonly stored in 1- or 2-pound packages.

Meat Safety

Freezing

- If you have slaughtered the animal yourself, wait until the meat has fully cooled before packaging. Packaging meat that is still warm can inhibit the efficacy of vacuum seal packaging. Meat should reach internal temperatures below 40°F as quickly as possible to slow microbial growth. Bacteria and pathogens thrive between 40°F and 140°F. This range is known as the Temperature Danger Zone. Waiting until the meat is as cold as possible reduces the chances that harmful bacteria can grow and multiply on the meat product.

- Freeze packages in a single layer if possible. Allowing cold air to circulate around all sides of the packages helps the meat to freeze as quickly as possible. The faster meat freezes, the less moisture (known as purge) will be released from the product, resulting in juicier meat when cooked. If your freezer has a quick freeze shelf, utilize it as much as possible.

- Freeze and store meat at or below 0°F at all times. Avoid temperature fluctuations caused by opening the freezer too often or poor temperature regulation.

- Keep your hands and work area clean. Wash your hands and work surfaces before beginning to cut and package your meat. If your hands become extensively soiled, wash them before touching the packaging or equipment. The cleaner you can keep the packages, the easier they will be to write on for labeling, vacuum bags will seal better, and the safer the packages will be to handle once they are frozen. Working with meat is an inherently messy job. Taking extra steps to do the job neatly will pay off in the end.

- Use frozen meat within 1 year for best quality. Proper freezing keeps meat safe for much longer than 1 year, but the best eating experience will be within 1 year of freezing.

Thawing

Proper thawing of meat can be done in one of three ways.

- Refrigerator. Remove the meat from the freezer and place it into a designated spot in your refrigerator. It should be placed on a tray or plate on the lowest rack possible with no ready to eat foods below or directly next to it. This will prevent cross contamination of raw and ready to eat foods such as fruits, vegetables, or other foods that do not get cooked before eating. Thawing meat in the refrigerator will take 1-4 days for most cuts so it does take some pre-planning. Refrigerator thawing is recommended for large cuts of meat such as roasts.

- Cold Water. If meat is paper wrapped or packaged without a vacuum seal place the package into a zip-top bag and seal it (this is not necessary for vacuum sealed packages). Place the package in a bowl in the sink and allow cold running water to flow over the package. The water does not need to be a heavy flow, a strong trickle will do. This method will thaw most small packages relatively quickly.

- Microwave. If you need meat thawed in a hurry, you can thaw meat using the defrost setting of your microwave. Exercise caution when using the microwave as this method may start to cook the meat. While cooking is not harmful, it can result in a lower quality eating experience for the consumer.

Meat should never be thawed on the countertop because it will be exposed to the temperature danger zone long enough to potentially create food safety issues.

Cooking

Proper cooking temperatures for pork products:

- Whole muscle roasts and chops should be cooked to a minimum internal temperature of 145°F. Allow the meat to rest after removing it from the heat for 3 minutes before cutting. Consumers can safely choose higher cooking temperatures depending on personal preferences.

- All ground meat should be cooked to a minimum internal temperature of 160°F.

Special Consideration for Pork

- Meat from pigs raised in certain environments may be infected with Trichinosis. This is a parasite that is transmitted to pigs by ingestion.

- Freezing pork meat for a minimum of 30 days at 5°F or cooking as suggested above will kill the parasite.

For more information on meat safety, view BBQ Bootcamp: Beef Safety and Handling.

The BBQ Bootcamp program is designed to educate consumers about beef selection, preparation, and use in meals. View this series of videos to learn more about choosing and safely preparing a variety of beef cuts.