Written by Heidi Carroll, former SDSU Extension Livestock Stewardship Field Specialist & Beef Quality Assurance Coordinator.

A good herd health plan involves both a vaccination program and treatment plan developed with your veterinarian. Approximately 70% of beef operations administer vaccines to cows and calves at least one time every 12 months (NAHMS, 2007–2008). Additionally, 68% of operations used oral or injectable antibiotics to treat disease in any cattle or calves. This annual financial investment in herd health products is important for animal well-being and production success. The ultimate success of these products is dependent on how we handle and administer them to the animal.

Management Tips

Here are some tips to simplify the task, stay organized, and keep safe chute side during processing or treating animals.

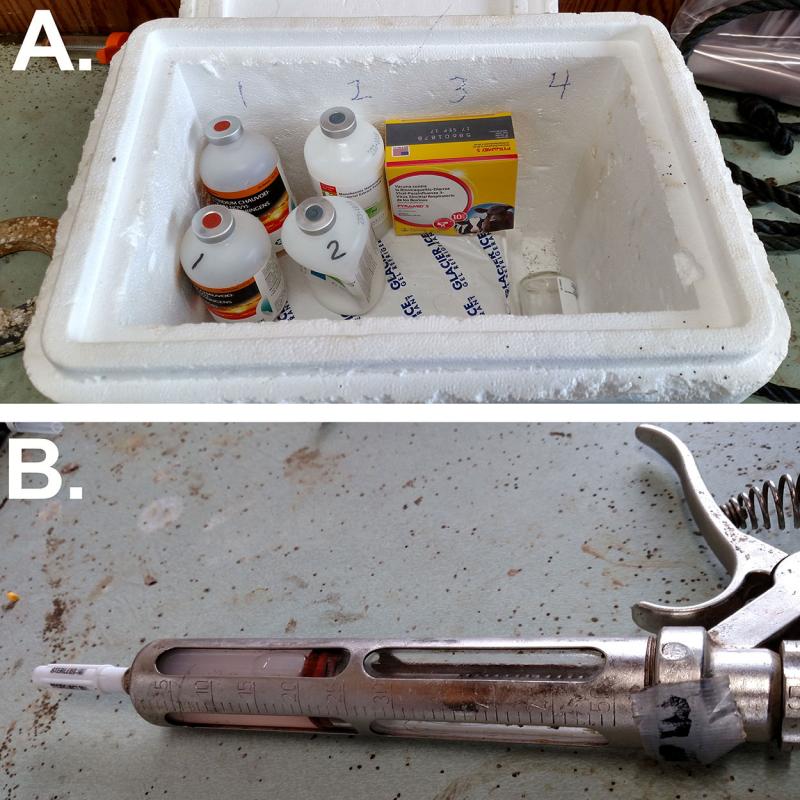

Start with clean, maintained equipment.

- Syringes should be clean, but care should be taken so the cleaning process doesn't leave residues that could inactivate live vaccines.

- To clean, draw up boiling water into the syringe barrel repeatedly for two-to-three minutes. Periodically, syringes can be taken apart and boiled for a more-thorough cleaning. However, some plastic or nylon syringes may not hold up to this process. Do not use detergents or disinfectants that can negatively impact vaccine efficacy. Once completely dry, store cleaned syringes in a dust-free environment, such as a Ziplock bag.

- Lubricate syringes with non-petroleum-based products (e.g. glycerin). Stoppers should be replaced when they or the plunger are difficult to move. If replacing them does not fix the problem, it is time for a new syringe.

- Learn more about home methods for sterilizing syringes at the National BQA YouTube Channel.

Keep vaccines cool and out of direct sunlight.

- Sunlight and ultraviolet (UV) light will inactivate live vaccines, so keeping vaccines and syringes in a cooler with ice packs while processing is critical. Most vaccines have storage temperatures of 35–45 degrees Fahrenheit (2–7 degrees Celsius) and should not be allowed to freeze. Continuous-feed syringes are difficult to keep all components sheltered from sunlight and weather extremes. When using these syringes, strive to protect the bottle, hose and syringe from UV light.

- Low-cost vaccine coolers can be made with a plastic bucket and lid or styrofoam cooler by cutting holes in the lid or side. More-elaborate vaccine coolers can be made with plastic coolers, pvc pipe and a drill. Here are instructions on how to make a Chute Side Vaccine Cooler from Oklahoma Cooperative Extension Service.

- Heavy-duty cooler sets are available to purchase. These coolers are effective to store product and supplies as well as stay organized, though justifying the added cost is important to consider.

Label everything and keep records.

- Label all vaccines to corresponding syringes with duct tape or different colored knobs and markers. In addition, label the place in the vaccine cooler that they should be returned to after every use to prevent mess ups when grabbing the syringe for the next animal. A simple 1, 2, 3 system can be utilized to alleviate any need to remember exact names of products.

- Ensure all vaccinations and treatments are properly recorded. Records can be paper or electronic. Beef Quality Assurance (BQA) recommendations are to keep all herd-health records for at least two years from the date of transfer or sale of cattle. Good records are critical to food safety for products that have withdrawal times and future herd health decisions.

Mix for less than 60 minutes.

- Mix enough modified-live virus (MLV) vaccine that will be used in 60 minutes or less. Since MLV vaccines should be used immediately and cannot be stored for future use, purchase bottle sizes appropriately to mix the smallest batch in case of breakdowns or additional interruptions.

- Use a sterile transfer needle to mix products. Always change needles prior to drawing up new doses into the syringe to prevent contamination of the entire bottle.

Check label for dosage and route of administration.

- Accurate dosing and proper routes of administration are key for product effectiveness. The last thing we want to do is give the wrong dose of a vaccine in the wrong method.

- Read labels and set syringes to the correct dosage before starting. Also, determine the correct method of administration (subcutaneous or intramuscular) and put the correct size and length of needle on the appropriate syringe.

Needle and product safety.

- Prepare a puncture-proof, labeled container with a lid for sharps disposal. Many suitable containers may be found around the house to meet this need, and options for purchase are also available. Learn more about sharps disposal.

Once everything is in order, processing cattle is much more enjoyable for everyone involved. Strive to utilize Beef Quality Assurance (BQA) best management practices by giving vaccinations in front of the shoulder in the neck region. Proper injection sites are not only safer for the animal and handler, but also optimize the meat quality and wholesomeness. Lastly, remember to clean everything up and inspect all equipment before properly storing. These simple steps can help maximize efficiency when working cattle, while also improving efficacy of health programs, leading to more-profitable cattle on the operation.

References:

United States Department of Agriculture, Animal and Plant Health Inspection Agency, Animal Health, NAHMS Beef Cow-Calf Studies. Beef 2007–08 Part IV: Reference of beef cow-calf management practices in the United States, 2007-08. Last accessed April 20, 2021.