Written collaboratively by Kelly Froehlich, former Assistant Professor & SDSU Extension Sheep and Goat Specialist, and Heidi Carroll, former SDSU Extension Livestock Stewardship Field Specialist & Beef Quality Assurance Coordinator.

With cooler weather comes an increase in the use of heaters, which is a top fire hazard in barns followed by electrical distribution and lighting equipment. This article provides a few examples that can be a source of concern in many sheep and goat barns. However, any electrical appliance and cords should be checked periodically and used according to the manufacturer’s direction.

Barn fires are devastating and, unfortunately, accidents happen all too easily with the many combustible sources found in facilities, including hay, straw, cobwebs, dust, garbage, and more. Therefore, the prevention of barn fires is a must to minimize the risk of loss to livestock and facilities. According to the National Fire Protection Association (NFPA) barn fire safety checklist, producers should ensure the following:

- Heaters and heat lamps are kept a safe distance away from any flammable source and are in a sturdy position.

- Wiring is to code and free from damage.

- Extension cords are not used within the barn.

- Lights and outlets are protected and regularly cleaned from dust and cobwebs.

- Feed, hay, straw, and flammable liquids are stored away from the main barn.

- Barn fire protocols and hazard checks take place.

The NFPA 150: Fire and Life Safety in Animal Housing Facilities Code provides specific details and recommendations for fire production systems, such as installing ABC-type fire extinguishers, fire alarms, and a sprinkler system in animal facilities. The full version of this code can be found the NFPA website. For most, these codes are not representative of a producer’s current barn situation. It is recommended when building or improving existing barns that these codes are considered. At a minimum, a fire extinguisher should be in the barn and the wiring of cords and appliances being used should be checked and replaced as needed.

Potential Fire Hazards Around a Sheep Farm

Heat Lamps

Around a sheep or goat farm, it is quite easy to find sources of potential fire hazards and examples of why the fire codes are written as they are. The first example of concern in the lambing and kidding barn is the use of heat lamps. In the Midwest, winter lambing and kidding means adverse weather conditions and temperatures with innate risk of hypothermia to lambs and kids. Use of heat lamps can provide extra warmth with the trade off for the potential of a fire hazard. At a minimum it is a great idea to use heat lamps that have some sort of protection around the bulb (see Figure 1). It is not uncommon for ewes to knock heat lamps or burn the back of their wool standing under them. Ideally, heat lamps should be secured well with something that is not flammable (for example, wire, not twine) and protected from ewes. One example of a method or an idea to ensure ewes will not knock the heat lamp while providing warmth to lambs is the use of a warming barrel (see Figure 2).

Heaters and Furnaces

The second example of fire hazards easily found in lambing barns is the use of heaters. This includes heaters and furnaces to warm a ‘hot room’ or water heaters. Space heaters are great for mitigating lamb loss due to hypothermia. However, it is important that the heaters are kept away from flammable sources, such as straw and hay. Additionally, it is important to remember that dust and cobwebs can be flammable, and often heaters are only used for a couple months of the year, resulting in several months of dust buildup. Use an air compressor to blow out dust from internal components prior to use.

Water Heaters

Water heaters are critical during the cold winter months and require daily checks and routine maintenance. All types of water heaters can provide a risk of fire hazard. Cords on built-in, insulated heater tanks should be inspected regularly for wear. Additionally, if electrical lines are buried in the ground in dirt floor barns, care should be taken so that lines are not accidentally exposed after repeated cleaning and scraping of manure and dirt fill over the years. Caution should be used on free-floating tank heaters (Figure 3).

Animals should not have access to cords with the potential to pull the heater out of the water. Floating tank heaters should preferably be used in a tank that is automatically filled. When used in plastic water tanks, wire guards around the element should be added, because a tank running dry is a recipe for a fire. When producers use these, all family members and employees should be reminded that daily water tank checks are critical for both animal care and fire prevention.

Extension Cords

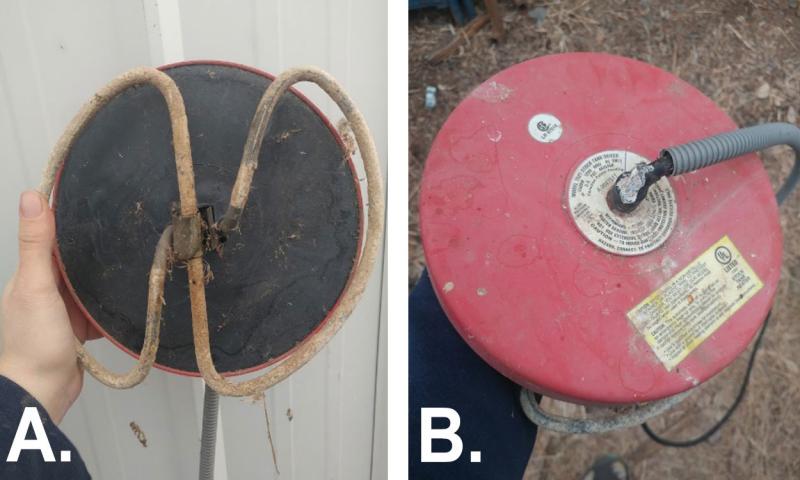

The last example that could represent a potential fire hazard is the use of extension cords. Outlets are never where they are needed, thus extension cords are often used. Although extremely convenient, extending cords across distances makes them prone to damage. Cords should be protected from being chewed on, driven on, and stepped on, as over time this creates wear. Cords that show wear to the outer plastic coating (Figure 4), missing a grounding (Figure 5), or have been corroded (Figure 6) should be replaced.

In Summary

Although the risk of a fire is always apparent where moisture and ignition sources are abundant, care should be taken to minimize potential risks where livestock are housed This is a gentle reminder as the kidding and lambing season progresses to be aware of the condition of your wiring and heating appliances to minimize the risk of a fire. Preventing wear and damage, conducting routine checks, replacing those that do show wear could help prevent a devastating fire. Additionally, following and consulting the National Fire Protection Association 150 code can help keep you, your livestock and barn safe for years to come.