Written collaboratively by Taylor Grussing, former SDSU Extension Cow/Calf Field Specialist and Warren Rusche, Assistant Professor & SDSU Extension Feedlot Specialist.

Corn silage harvest is in full swing with warm fall days in the forecast, choppers likely won’t be slowing down any time soon. Silages make up a large component of beef cattle winter rations in the Upper Midwest, therefore it is critical that it is harvested correctly to make high quality, cost effective feed for the next year. However, drought conditions this summer may have forced some producers to begin chopping silage earlier than normal to begin feeding cow/calf pairs or early weaned calves. There isn’t any one size fits all procedure for how to feed corn silage. Yet, two key points to keep in mind when making high quality silage are moisture content before harvest and nutrient content before feeding.

Testing Silage Moisture

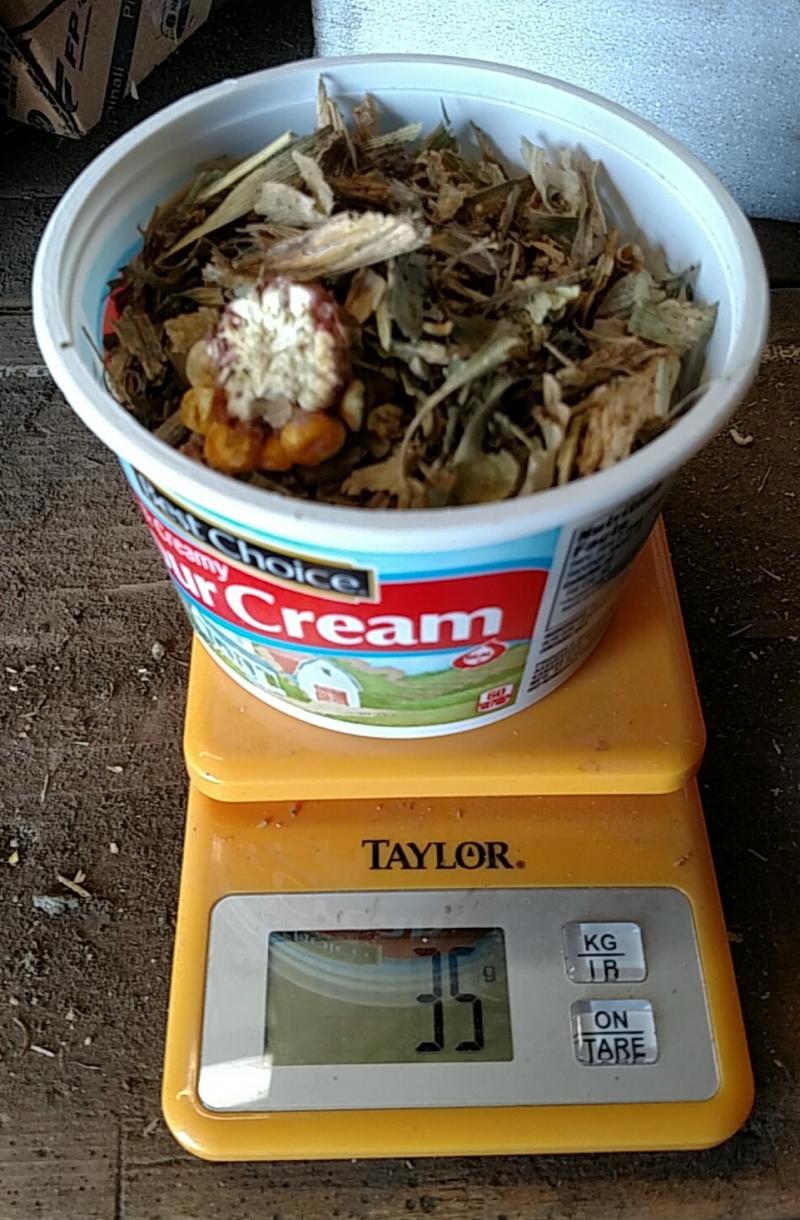

Ideally corn silage should be chopped when the kernel is at ½ to 2/3 milkline and at 32 – 38% dry matter. The milkline can be variable between hybrids, so the best method is to do a sample harvest before cutting the whole field. Either with the chopper or by hand, harvest a part of the field and determine the moisture using a gram scale and either microwave or Koster Moisture Tester. Research from Penn State showed a very close relationship between these two on farm methods compared to the forced-air oven standard used in laboratories (Pino and Heinrichs, 2014).

Microwave Method

With the use of a microwave, electromagnetic radiation is used to eliminate water molecules and dry samples down.

- Gather a silage sample, gram scale, paper plate or bowl, glass of water and microwave oven.

- Place glass of water in the back corner of microwave.

- Dry paper plate in over on high power for 1 – 1.5 minutes. Weigh the dry plate immediately.

- Weigh 100g of silage onto the dry plate.

- Begin drying process at 50% power for 4 minutes. Weigh sample.*

- This step may need to be repeated several times in order to complete they drying process. Reduce microwave drying time as the sample dries. Any char on the sample means the power was too high and or dried too long, and a new sample should be analyzed.

- Check weight of the sample until weight change is less than 2 grams.

Koster Moisture Tester Method

Unlike a microwave, which utilizes electromagnetic radiation is to eliminate water molecules and dry samples down, a Koster Moisture Tester relies on directing hot air over the samples to dry down.

- Gather silage sample, gram scale and Koster tester.

- Turn on scale and weigh receptacle. Note weight and add 100 g of silage sample.

- Place receptacle with sample on top of the heating system for 30 minutes.

- Weigh the sample and continue to weight at 10 minute intervals until weight change is less than 2 grams repeatedly.

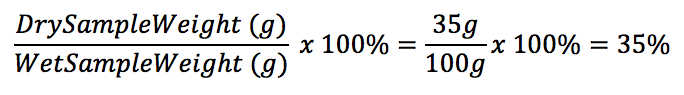

Calculating Percent Dry Matter

Once the sample is dry by either method, the percent dry matter can be calculated as follows:

*Remember to account for the paper plate weight for both the dry and wet sample weights.

If the plant is to wet (<30 % DM), the field should remain standing for a few days more days. As a rule of thumb, dry down of corn fields is 0.5% per day. Therefore, if this test reveals the field is at 29% DM and 33% DM is desired for harvest, wait approximately 8 days to harvest.

The Bottom Line

Harvesting silage too early at a will lead to poor fermentation, possible spoilage and seepage of valuable nutrients out of the bunker. Dry conditions took a toll on several corn fields across the country this year, but just because the corn plant looks dry doesn’t always mean it is ready to chop. Immature corn in these fields are resulting in greater in moisture content than meets the eye. So making moisture testing part of the field before chopping it all can help prevent more loss of nutrients and make better feed going into the winter.

Reference:

Pino, F.H. and A. J. Heinrichs. 2014. Comparison of on-farm forage-dry-matter methods to forced-air oven for determining forage dry matter. Prof. Anim. Sci. 30:33.