One of the last projects I was involved with as coordinator for the Lower James River Watershed Project was the installation of a deep pit monoslope barn for a feedlot operation near Alexandria, SD. A deep pit confinement barn is a manure storage system that employs slatted flooring with pit manure storage underneath. Beef producers value the labor-saving advantages that typically come with a deep pit design along with the increased nutrient retention of the manure.

The Challenge

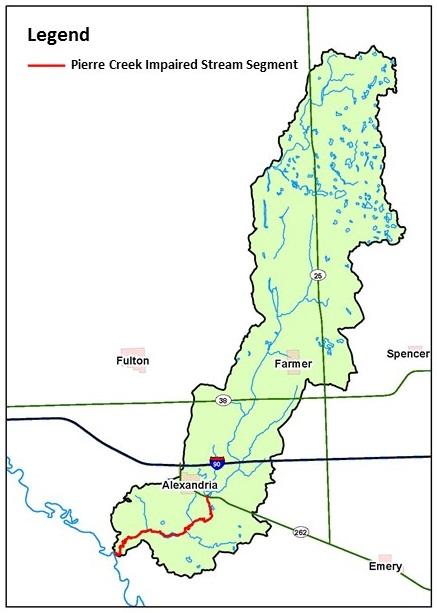

The farm is located within the Pierre Creek watershed; which according to the 2014 South Dakota Integrated Report for Surface Water Quality Assessment (SD DENR 2014), does not support its beneficial use designation for limited contact recreation beginning near Alexandria, SD to the James River (Figure 1). The listed cause for the impairment is fecal coliform bacteria and Escherichia coli. Fecal coliform bacteria are a group of organisms whose presence in a water sample generally indicates recent fecal contamination from animals or humans. A positive test may also indicate the presence of disease-causing pathogens. E. coli is the most predominant species in the fecal coliform group. For fecal coliform bacteria samples, the standard for limited contact recreation is 1,000 colonies per 100 mL (mean) or 2,000 colonies per 100 mL (single sample). For E. coli, the standard is 630 colonies per 100 mL (mean) and 1,178 colonies per 100 mL for a single sample.

Waste Management Options

Because of the nature of the impairment and the operation’s proximity to Pierre Creek, it was thought to be in the producer’s best interest to look at an animal waste management system and take advantage of the cost-share opportunities that existed for priority feeding operations within the larger Lower James River basin. A feasibility study was conducted where different options were investigated, including an open lot with a lagoon system and a bedded confinement facility. Ultimately, it was decided that a deep pit monoslope barn was the best option for the producer because of the perceived labor-savings and efficiency of the system.

Monoslope Barn Benefits

Beyond the advantages a monoslope barn can provide livestock (shade from the sun, mud-free pens, etc.), a benefit that the deep pit portion of the system offers is the manure nutrient concentration. Table 1 estimates the nutrient concentration of manure from a number of different storage systems. While open lots will typically have the lowest manure handling cost, they will also have the lowest nutrient capture and value. Confinement buildings generally retain more nutrients but involve more labor in cleaning and land application. Pit-stored manure captures more nutrients versus other types of facilities, as less nitrogen is lost to volatilization and fewer environmental interactions are allowed to occur (ISU 2015).

| N lbs. | P2O5 lbs. | K2O lbs. | |

|---|---|---|---|

| Solid manure from open lots – variable Dry Matter |

15 | 8 | 11 |

| Manure from bedded confinement – 30% DM |

18 | 11 | 14 |

| Liquid deep pit manure – 10% DM |

45 | 24 | 36 |

In Table 2, it is estimated that one head space will produce 3 tons of solid manure per year in an open lot, 5 tons of manure per year in a bedded confinement system, and 2,500 gallons of manure per year in a deep pit system. By multiplying the nutrient concentrations in Table 1 by the volume produced per head space, you can begin to compare each system against the other as it relates to the value of the manure as you land apply it to your fields.

| Estimated annual amount of manure per head (tons or gallons for application) |

N lbs. | P2O5 lbs. | K2O lbs. | |

|---|---|---|---|---|

| Solid manure from open lots | 3 tons | 45 | 24 | 33 |

| Manure from bedded confinement | 5 tons | 90 | 55 | 70 |

| Deep pit manure | 2,500 gallons | 113 | 60 | 90 |

References:

- Iowa State University. Beef Feedlot Systems Manual. PM 1867. January 2015.

- South Dakota Department of Environment & Natural Resources. The 2014 South Dakota Integrated Report for Surface Water Quality Assessment. Pierre, SD.