Written collaboratively by Adam Varenhorst, Philip Rozeboom, Patrick Wagner, Brad McManus, Stephen Robertson, Eric Jones, and Madalyn Shires.

Pesticide labels provide guidance on the personal protective equipment (PPE) required for handling pesticide products. Because hands are the most common areas exposed to pesticides, safety gloves are among the most important pieces of PPE. We use our hands for so many different jobs. If our hands are contaminated with pesticides, there is a chance to leave pesticide residue on everything we touch, which may expose people or your own unprotected skin.

Due to the high chance of exposure, prior to handling a pesticide the label should be reviewed, and the proper glove material should be obtained. For fumigants, the label may state the gloves should not be used (e.g., methyl bromide) or that dry cotton gloves should be used (e.g., aluminum phosphide). Pesticide labels will provide guidance that is essential for the removal and handling of pesticide-contaminated gloves. After discarding gloves always wash your hands using hot water and plenty of soap. In the field, it is important to remember to have the means to wash your hands if you have left the sprayer cab for any reasons as all parts of the sprayer should be considered contaminated.

Solvent Categories

Selecting the right glove material is very important. Not all materials provide the same protection to the various solvents and chemicals used in pesticide formulations. Some solvents may even degrade or dissolve incompatible PPE, effectively increasing the risk of physical harm. Pesticide labels identify what materials effectively protect against each product and are required to be worn. Label instructions must always be followed. To highlight the compatibility differences between PPE and pesticide solvents, Table 1 details compatibilities between solvent categories provided on the pesticide label and the type of glove materials. Never use gloves that are lined with cloth/cotton material when working with pesticides, as these can’t be properly cleaned and increase the risk of chronic exposure to pesticides.

|

|

||||||||

|---|---|---|---|---|---|---|---|---|

| Solvent Category (On label) |

Barrier Laminate |

Butyl Rubber* |

Nitrile Rubber* |

Neoprene Rubber* |

Natural Rubber* |

Poly- ethylene |

Polyvinyl Chloride (PVC)* |

Viton* |

| A (dry and water-based formulations) |

High | High | High | High | High | High | High | High |

| B (ketones) |

High | High | Slight | Slight | None | Slight | Slight | Slight |

| C (alcohols) |

High | High | High | High | Moderate | Moderate | High | High |

| D (acetates) |

High | High | Moderate | Moderate | None | None | None | Slight |

| E (aliphatic petroleum distillates) |

High | Slight | High | High | Slight | None | Moderate | High |

| F (aromatic petroleum distillates) |

High | High | High | Moderate | Slight | None | Slight | High |

| G (aromatic petroleum distillates) |

High | Slight | Slight | Slight | None | None | None | High |

| H (halogenated hydrocarbons) |

High | Slight | Slight | Slight | None | None | None | High |

1 This table was adapted from the EPA Chemical Resistance Category Selection Chart for Gloves and the EPA Labeling Revisions Required by the Worker Protection Standard (WPS).

* These material ratings are based on gloves that are greater than or equal to 14 mils in thickness. Natural rubber includes natural rubber blends and laminates.

Material Ratings

The rating explanation for the types of glove material are listed below:

- High: Glove materials with this rating are highly resistant to the associated solvent. These types of gloves should be cleaned or replaced at the end of each use or the end of the day. They should still be rinsed off at rest breaks to reduce the potential for exposure.

- Moderate: Glove materials with this rating are moderately resistant to the associated solvent. These types of gloves should be cleaned or replaced within 1-2 hours of exposure.

- Slight: Glove materials with this rating are slightly resistant to the associated solvent. These types of gloves should be cleaned or replaced within 10 minutes of exposure.

- None: Glove materials with the none rating have no resistance to the associated solvent. These should not be used.

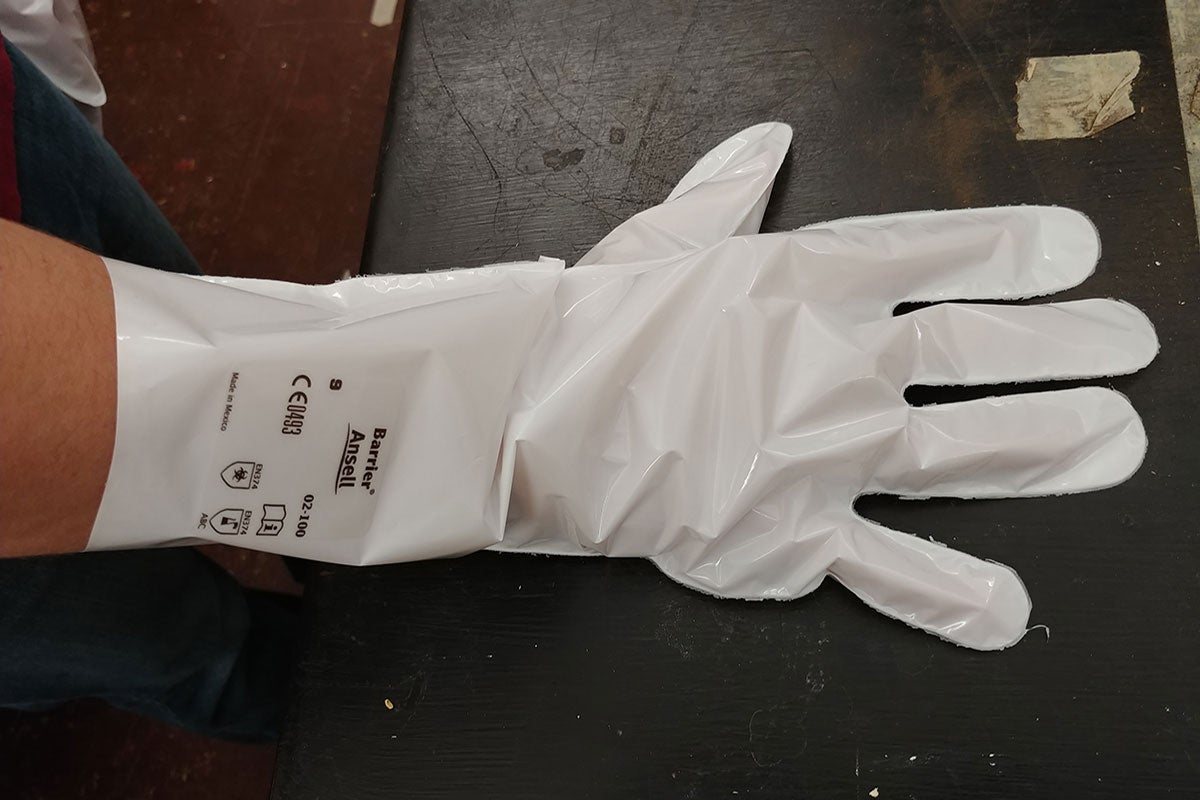

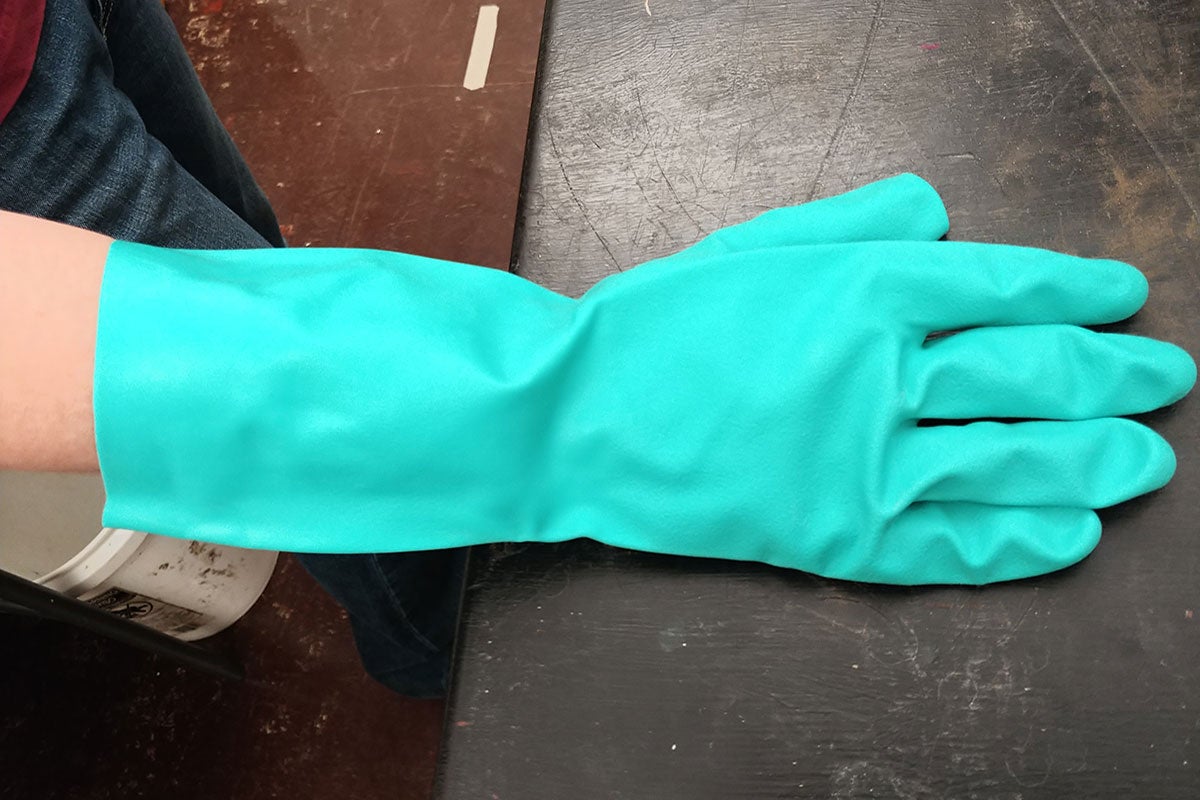

Of the different materials available for gloves, barrier laminate gloves (Figure 1) are highly resistant to all listed solvents. Although nitrile rubber (Figure 2) and butyl rubber (Figure 3) gloves are not highly resistant to all solvents, they are less expensive and can often be reused when properly cleaned and maintained. In some cases, it is recommended to wear a barrier laminate glove as a liner of a butyl rubber or nitrile rubber glove. This will ensure proper protection from exposure while minimizing the risk of glove failure due to a tear. If any PPE becomes compromised (tears, breaks, internal and irreversible contaminations, etc.), it should be discarded according to the label instructions for soiled or contaminated PPE without reusing it.

Barrier Laminate

Nitrile Rubber

Butyl Rubber