During the last few years there has been an explosion in the popularity of ready-to-drink (RTD) energy drinks. Many of the energy drinks that are new to the market have no added sugars. These energy drinks can be consumed prior to workouts, but they are also consumed when a consumer is looking for some extra energy. This article will help address the food safety concerns in making a safe RTD energy drink.

Hazard Evaluation

When considering the safety of a product, it is always important to consider the hazards that must be considered as part of a food safety evaluation. These hazards include physical (glass, metal, plastic, stems, rocks, etc.), chemical (allergens, mycotoxins, chemicals, etc.) and biological (parasites, pathogens, viruses, etc.). However, let’s first consider the steps of how carbonated RTD energy drinks may be made.

Ingredient Overview

Many of the ingredients that are in energy drinks can be considered ready-to-eat (RTE). These ingredients can include citric acid to reduce pH; natural and artificial flavors to impart a product’s specific flavor; artificial and natural colors to impart a product’s specific color; caffeine, which acts as a source of energy; preservatives, such as potassium sorbate and sodium benzoate; vitamins, which can act as a source of energy; artificial sweeteners, which act as a source of no-calorie flavor enhancement; extracts, which may act as nutritional supplements and many other ingredients that are used for the purpose of acting as a nutritional supplement.

Many of these ingredients are considered RTE based on their food safety property, such as low water activity and how they are processed chemically or thermally. Although these ingredients are considered low risk, it is still the responsibility of the processor to perform an ingredient hazard analysis on each individual ingredient to ensure that the ingredients are considered RTE. Lastly, the source of water is vitally important. Ensuring that the quality of water is potable and ready to drink (RTD) is just as important as ensuring the other ingredients are RTE. If the source of water is city water, there are requirements needed by the city to ensure that it meets potable water standards set forth by the EPA. The city water results should be publicly available, and this will be an important piece of documentation for the hazard assessment of water. If the source of water is well water, there will be more work needed to ensure that the water meets potable water standards. This should include the evaluation of physical, chemical, biological and radiological hazards.

Process Overview

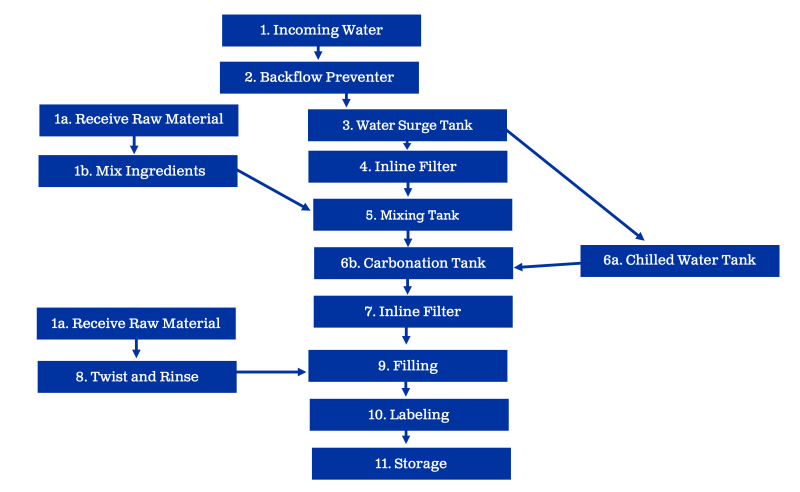

Having a good understanding of the process is essential in understanding the risks associated with processing. The incoming water is received, and, as previously discussed, it’s important to know the source of the water to make an informed assessment of the water.

Materials are typically received in and stored at ambient temperature. The ingredients can either be mixed in a blender to make the dry component mix, or they can be added into a mixing kettle that will mix the ingredients. Screens are utilized in the system to monitor for foreign material that is generated due to equipment failures or foreign material, which may come from outside the system. These screens are checked intermittently to monitor for foreign material.

If a mixing tank is utilized, the dry-blend ingredients are added along with water to ensure there is a homogenous mix. A chilled water tank is utilized to bring the water to the desired temperature. The carbonation tank is a holding tank where the mixed slurry has chilled water added to it and where the solution becomes carbonated.

A twist and rinse system will be used before the cans are filled. The twist and rinse system or a like system will rinse the bottles with water to remove any foreign material or dust that may be in the can. The cans are then filled with product and then sealed. Finally, the cans may be labeled if they are not already pre-labeled by the can manufacturer.

Food Safety Characteristics of Carbonated Energy Drinks

There are several food safety characteristics in carbonated RTD energy drinks that make it a safe product. These factors include pH and carbonation. Having a low pH is important, as it can limit the growth of bacteria, as well as create a bactericidal environment for certain bacteria. It is important to understand the pH of each individual product, as this may potentially vary depending on the type of ingredients which are used. Additionally, carbonation acts as another characteristic that prevents growth of certain microorganisms and can actually be bactericidal at a given volume and pressure, as noted in “The Effect of Carbonation on Bacteria in Beverages.” There is also a paper that was published by P.P. Wareing and R.R. Davenport on “Microbiology of soft drinks and fruit juices.” In this paper, it noted that, for carbonated drinks, mold and bacterial growth is very unlikely, as both types of microorganisms are very sensitive to carbon dioxide. Combase, a microbiological modeling program was used to predict non-thermal survival of Listeria and Salmonella at given conditions (i.e. 68F, 3.5 pH and Aw of 0.96 for Listeria and 68F, 4.3 pH, and Aw of 0.96 for Salmonella) found that Salmonella will have a 1.24 log reduction in 120 hours or five days and Listeria will have a 2.54 log reduction in 120 hours or five days. The combination of using RTE ingredients, a safe source of water, the low pH of the final product, manufacturing in a hygienic environment and carbonation makes RTD energy drinks a relatively safe product.

Chemical Hazards

Since agricultural ingredients are typically not used in RTD energy drinks, there is a much lower risk of molds, and, thus, mycotoxins and aflatoxins. However, mycotoxins and aflatoxins should be evaluated for each ingredient.

Physical Hazards

Depending on the ingredients that are used, there could be a risk of physical hazards. Thankfully, food manufacturers have several foreign material control devices and programs in place to ensure that hazardous foreign material is not present in the incoming ingredient. Although the RTD processing system can remain relatively closed to the environment, it is important to have foreign material detection devices (such as screens, filters, strainers, etc.) to actively monitor for foreign material that can enter the system or be generated by the system. Having a screen, filter or strainer close to the terminal end of the processing system is best to ensure that the final product is free from hazardous foreign material.

Conclusion

When making a RTD energy drink, it is important to consider how the product will be made and processed. Carefully evaluating the ingredients as well as water is an important step. It is also important to ensure that the pH of the product is understood, as the pH can act as a barrier to pathogen growth. Utilizing carbonation also acts as a hurdle in making RTD energy drinks safe. It is important to note the volume of carbonation used, as well as the pressure, as this may have different effects on microorganisms. The equipment needed to make a carbonated RTD energy drink may not be available without a sizable financial commitment. However, there is a contract manfacturing company in Woonsocket, South Dakota called Dak Pak that can produce RTD Energy Drinks at a commercial level. If you develop a RTD energy drink and would like to consider commercializing your product, a good next step could include finding a contract manufacturer, such as Dak Pak, to make your product.

Document Sources

- Wareing, Peter & Davenport, R.. (2007). Microbiology of Soft Drinks and Fruit Juices. 10.1002/9780470995822.ch11.

- Donald J.T., Jones C.L & MacLean A.R.M. The Effect of Carbonation on Bacteria in Beverages.